Choosing between air-cooled and water-cooled machines depends on your needs and environment. Air-cooled systems are simpler, easier to maintain, and better for smaller setups or limited water access, but they can be noisier and less efficient in hot conditions. Water-cooled machines offer higher efficiency and better performance for demanding tasks, though they require more complex setup and maintenance. To find out which suits your situation best, explore the details ahead.

Key Takeaways

- Water-cooled systems offer higher efficiency and are better for demanding, high-performance applications.

- Air-cooled machines are simpler, easier to maintain, and suitable for smaller or less complex setups.

- Water-cooled units tend to have higher initial costs but lower long-term operational expenses.

- Air-cooled systems perform less effectively in high-temperature environments and generate more noise.

- Choose based on resource availability, environmental conditions, and your balance of initial and ongoing maintenance costs.

When choosing between air-cooled and water-cooled machines, understanding their differences can help you make an informed decision. Both systems have unique advantages and drawbacks that impact your overall operation, especially regarding energy efficiency and maintenance requirements. Knowing which system suits your needs can save you time, money, and headaches down the line.

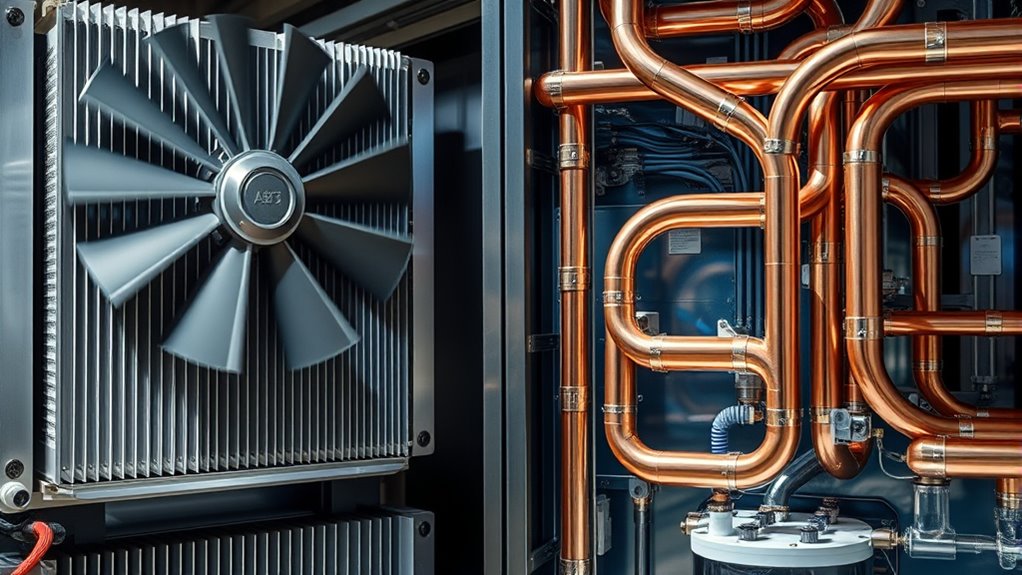

Air-cooled machines rely on fans and heat sinks to dissipate heat into the surrounding environment. They tend to be more straightforward in design, often requiring less initial setup, which makes them ideal for smaller or less complex applications. Because they don’t need water or other coolants, their energy efficiency is generally lower compared to water-cooled systems, especially when operating under heavy loads. However, their simplicity translates into lower maintenance requirements—there are fewer parts that can fail, and you don’t have to worry about leaks or water quality issues. Regular cleaning of the fans and heat sinks is usually enough to keep an air-cooled machine running smoothly, which makes upkeep fairly manageable. Additionally, their reduced complexity can make troubleshooting and repairs simpler for non-experts. Furthermore, environmental factors such as ambient temperature can significantly influence their cooling performance, making them less suitable for high-temperature environments. Additionally, air-cooled systems may generate more noise during operation, which could be a consideration in noise-sensitive settings. Proper airflow management is essential to optimize their cooling efficiency and prevent overheating.

Air-cooled machines are simple, requiring less maintenance but offering lower energy efficiency than water-cooled systems.

In contrast, water-cooled machines use liquid coolant to transfer heat away from components more effectively. This process allows them to operate at higher efficiencies, especially in demanding environments or when dealing with continuous, heavy workloads. The higher energy efficiency of water-cooled systems means they often consume less power to achieve the same cooling performance, which can translate into lower operational costs over time. But this efficiency comes with increased maintenance requirements. You need to regularly check coolant levels, monitor for leaks, and ensure the water quality remains suitable to prevent corrosion or microbial growth. The complexity of these systems also means that repairs and upkeep tend to be more involved and costly if issues arise. For optimal performance, many water-cooled systems incorporate temperature regulation mechanisms, which can add to their complexity but improve reliability under varying conditions. Proper system design is essential to prevent issues like coolant contamination or system failure, emphasizing the importance of professional installation and maintenance. A well-designed water-cooling setup can adapt to fluctuating workloads and environmental conditions, enhancing overall system longevity.

Choosing between the two depends on your specific needs. If you prioritize ease of maintenance and lower upfront costs, an air-cooled machine might be your best bet. They are typically more resilient in environments where water availability is limited or where simplicity is valued. However, if you’re looking for maximum energy efficiency and are prepared to handle more involved maintenance, water-cooled systems could be more advantageous—especially for larger-scale or more demanding applications. Consideration of ongoing maintenance and environmental factors is also important, as water-cooled systems may require additional resources to operate efficiently over time. Ultimately, your decision should consider not just initial costs, but also ongoing maintenance, operational efficiency, and environmental factors. By understanding these key differences, you can select a cooling system that aligns with your operational goals and resource capabilities.

Air Exhaust Fitting, Manual and Automatic G 1/4" Water-Cooled Adjustable Air Evacuation Valve for Computer Water Cooling System(Black+Red)

Easy to install and easy to use.

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

Which Cooling Method Is More Environmentally Friendly?

You’re wondering which cooling method is more environmentally friendly. Water-cooled systems often have higher energy efficiency because they better manage heat, reducing overall resource consumption. However, they may use more water resources, impacting sustainability. Air-cooled machines typically consume less water but might be less efficient, leading to increased energy use. Consider your local resources and energy priorities to choose the most eco-friendly option for your needs.

How Do Initial Costs Compare Between Air and Water Cooling?

They say “you get what you pay for,” and that’s true with cooling systems too. When comparing initial costs, air-cooled machines usually have lower installation expenses, making them budget-friendly upfront. Water-cooled systems, however, tend to have higher setup costs due to additional components and complexity. Consider your long-term needs and budget, as the initial investment can influence overall expenses, but don’t forget to weigh efficiency and maintenance costs too.

Can Water-Cooled Systems Operate Effectively in Cold Climates?

Water-cooled systems can operate effectively in cold climates if you consider climate adaptability and proper insulation requirements. You might need to implement additional insulation around the system to prevent freezing, especially in extremely cold temperatures. With the right setup, water-cooled machines can maintain efficient cooling without performance issues. Just make certain you monitor the system for potential freezing risks and add safeguards like antifreeze solutions when necessary.

What Are the Long-Term Maintenance Requirements for Each System?

Did you know that water-cooled systems typically require maintenance every 6 to 12 months, compared to air-cooled systems needing attention every 1 to 2 years? You should regularly check coolant levels and clean water filters for water-cooled setups, ensuring component durability. For air-cooled machines, keep fins and fans clean. Consistent maintenance extends lifespan and keeps your systems running efficiently, saving you money in the long run.

Are There Any Noise Level Differences Between Air and Water Cooling?

When comparing noise levels, you’ll find that air-cooled systems typically produce more sound due to the fans actively running to dissipate heat. Water-cooled systems tend to have quieter sound levels because they rely on liquid circulation, which generates less noise. If noise comparison matters to you, water cooling offers a quieter operation, making it ideal for environments where minimizing sound is a priority.

Thermalright Aqua Elite 240 V3 Water Cooling CPU Cooler, Double PWM ARGB Fans with S-FDB Bearings,Efficient PWM Controlled Pump,for AMD/AM4/AM5, Intel LGA1150/1151/1200/2011/1700, (AE240 V3)

【Better Cooling】 The cooler adopts the fourth generation pump head + 240 cold row size black aluminium fin…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

So, whether you choose air or water cooling, one thing’s clear—you’re still trusting technology to keep things from overheating. Ironically, the “simple” air system might end up being more complicated than you think, while water cooling offers a sleek solution but comes with its own risks. Whichever you pick, just remember: no cooling method is perfect, and sometimes, the hottest machines need the coolest solutions—literally.

Easy Cloud Computer Fan with AC Plug, 120mm Variable Speed Axial Muffin PC Fan with Controller 120V 110V 220V Small 12V Case Cooling for PC Server Cabinet DVR TV Router Receiver Xbox Greenhouse

【Speed Controllable】Easy Cloud axial fan 120v allows you to freely adjust the computer cooling fan speed according to…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Thermalright FW360 Black ARGB CPU AIO Cooler,PC 360 Specification Water Cooler System,IPS LCD Screen with 320×240 Resolution,for AM5&Intel LGA1700/1851,CPU Cooler Comes with 2.4-inch LCD Display

[LCD screen water pump]The pump of the water-cooled cooler is a new generation of water pump system, which…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.