The science behind ice cream machines combines mechanical parts like paddles and motors with thermodynamic principles to produce smooth, creamy treats. The paddles churn the mixture, incorporating air, while the refrigeration cycle cools it rapidly through compression, expansion, and heat exchange. Precise temperature control prevents ice crystals from forming, ensuring a silky texture. Understanding how these systems work together reveals the fascinating science behind perfect ice cream—if you continue exploring, you’ll uncover even more amazing details.

Key Takeaways

- Ice cream machines combine thermodynamics and refrigeration cycles to rapidly cool and freeze the mixture, ensuring a smooth texture.

- Mechanical components like paddles and gears facilitate thorough mixing, incorporating air and preventing ice crystal growth.

- The refrigeration cycle involves compression, condensation, expansion, and evaporation to maintain optimal freezing temperatures.

- Temperature sensors and automatic controls ensure consistent cooling, preventing icy or grainy textures in the final product.

- Mechanical and cooling systems work together, utilizing heat transfer principles to produce high-quality, creamy ice cream.

Ice cream machines work by combining science and engineering to transform liquid ingredients into smooth, frozen treats. When you operate an ice cream machine, you’re engaging with a complex interplay of mechanical components and advanced cooling systems. These elements work together seamlessly to ensure your ice cream turns out perfectly creamy and consistently textured. The mechanical components, such as paddles, motors, and gears, are essential for mixing and churning the mixture. As the motor powers the paddles, they rotate to incorporate air into the mixture, which helps achieve that light, fluffy consistency you crave. These mechanical parts also prevent ice crystals from forming too large, maintaining the smooth texture you expect from high-quality ice cream.

Ice cream machines combine engineering and science to create smooth, creamy frozen treats through precise mechanical and cooling systems.

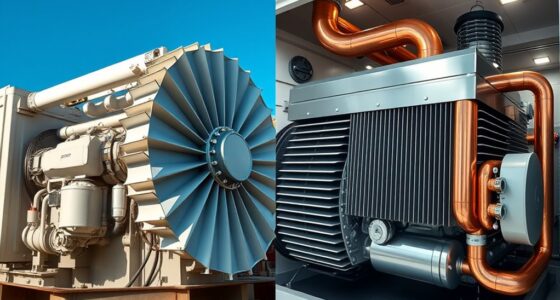

Cooling systems are the backbone of this transformation process. Inside the machine, a refrigeration unit cools the mixture rapidly, lowering its temperature below freezing point without solidifying it into a solid block. This is achieved through a cycle involving a compressor, condenser, expansion valve, and evaporator. The compressor compresses refrigerant gas, raising its temperature and pressure. The hot, high-pressure refrigerant then moves through the condenser coils, where it releases heat to the surrounding environment and condenses into a liquid. It then passes through an expansion valve, which reduces pressure and temperature, sending the cold refrigerant into the evaporator coil. Here, the refrigerant absorbs heat from the ice cream mixture, cooling it swiftly. This cycle repeats continuously, maintaining a consistent temperature that prevents ice crystals from growing too large and guarantees the mixture remains in a semi-frozen state. Thermodynamics plays a crucial role in optimizing this cooling process.

The efficiency of these cooling systems directly impacts the quality of your ice cream. If the cooling is too slow or uneven, you risk getting a texture that’s icy or grainy. Modern machines often include temperature sensors and automatic controls to monitor and adjust the cooling process, guaranteeing that the mixture freezes uniformly. The mechanical components also play a crucial role in maintaining this consistency. They keep the paddles moving at just the right speed, ensuring thorough mixing and proper incorporation of air. This not only improves texture but also prevents ice buildup on the sides of the container, which can compromise the final product. Additionally, heat transfer principles are essential for understanding how rapid cooling is achieved within the system.

Understanding these core mechanisms reveals how intricate and precise the science behind ice cream machines truly is. From the mechanical components that churn and mix to the cooling systems that rapidly freeze the mixture, every part is designed to work in harmony. When you see an ice cream machine in action, you’re witnessing a fascinating blend of physics, thermodynamics, and engineering—all working together to turn simple ingredients into a delicious frozen dessert. The cooling cycle is just one example of how thermodynamics plays a vital role in the process. Proper maintenance of refrigeration components ensures consistent performance and high-quality results.

Frequently Asked Questions

How Do Ice Cream Machines Prevent Ice Crystal Formation?

You might wonder how ice cream machines prevent ice crystal formation. They achieve this through ice crystal control by constantly churning the mixture, which keeps crystals small. Additionally, freezing point regulation guarantees the mixture stays just below freezing without forming large crystals. This combination creates a smooth texture, making your ice cream irresistibly creamy. Proper ice crystal control and freezing point regulation are key to perfect, velvety ice cream every time.

What Is the Role of Churning Speed in Ice Cream Texture?

Ever wondered how your ice cream gets that perfect smoothness? Churning speed plays a vital role in texture control. When you increase the churning speed, air gets whipped into the mixture, creating a lighter, creamier texture. Conversely, slower speeds produce denser ice cream. You can control the creaminess by adjusting the churning speed, ensuring your treat hits just the right spot. So, is your machine set for the ideal ice cream texture?

How Do Temperature Sensors Optimize Ice Cream Freezing?

Temperature sensors enhance ice cream freezing by providing real-time data that helps control the process. You’ll find that sensor calibration guarantees accuracy, preventing over- or under-freezing. This precise temperature regulation maintains the ideal consistency and texture. By constantly monitoring and adjusting the temperature, the machine ensures your ice cream freezes evenly, resulting in a smooth, creamy treat. Proper sensor calibration is essential for consistent quality and ideal freezing conditions.

What Materials Are Best for Ice Cream Machine Components?

Your ice cream machine works like a well-oiled superhero, thanks to the right materials. You should choose stainless steel for its unbeatable durability and wear resistance, ensuring your machine withstands countless frozen treats. Food-grade plastics are also excellent for parts that contact ingredients, offering safety and longevity. These materials keep your machine running smoothly, preventing wear and tear, so you can enjoy perfect ice cream every time without worries about component failure.

How Does Air Incorporation Affect Ice Cream Consistency?

Air infusion plays a vital role in determining ice cream consistency. When your machine incorporates air, it creates foam formation within the mixture, making the ice cream lighter and smoother. Too much air can lead to a fluffy texture, while too little results in denser ice cream. You can adjust the air infusion to achieve your preferred creaminess, ensuring the perfect balance between richness and texture for your ideal scoop.

Conclusion

Now that you know how ice cream machines work, you can see they’re like magic wands turning simple ingredients into frozen delights. With each spin, they choreograph a chilly dance, blending science and artistry to craft your favorite treat. So next time you enjoy that creamy scoop, remember it’s the brilliant orchestration of cold, motion, and innovation working behind the scenes—making dessert dreams come true, one swirl at a time.